ALL PRODUCT

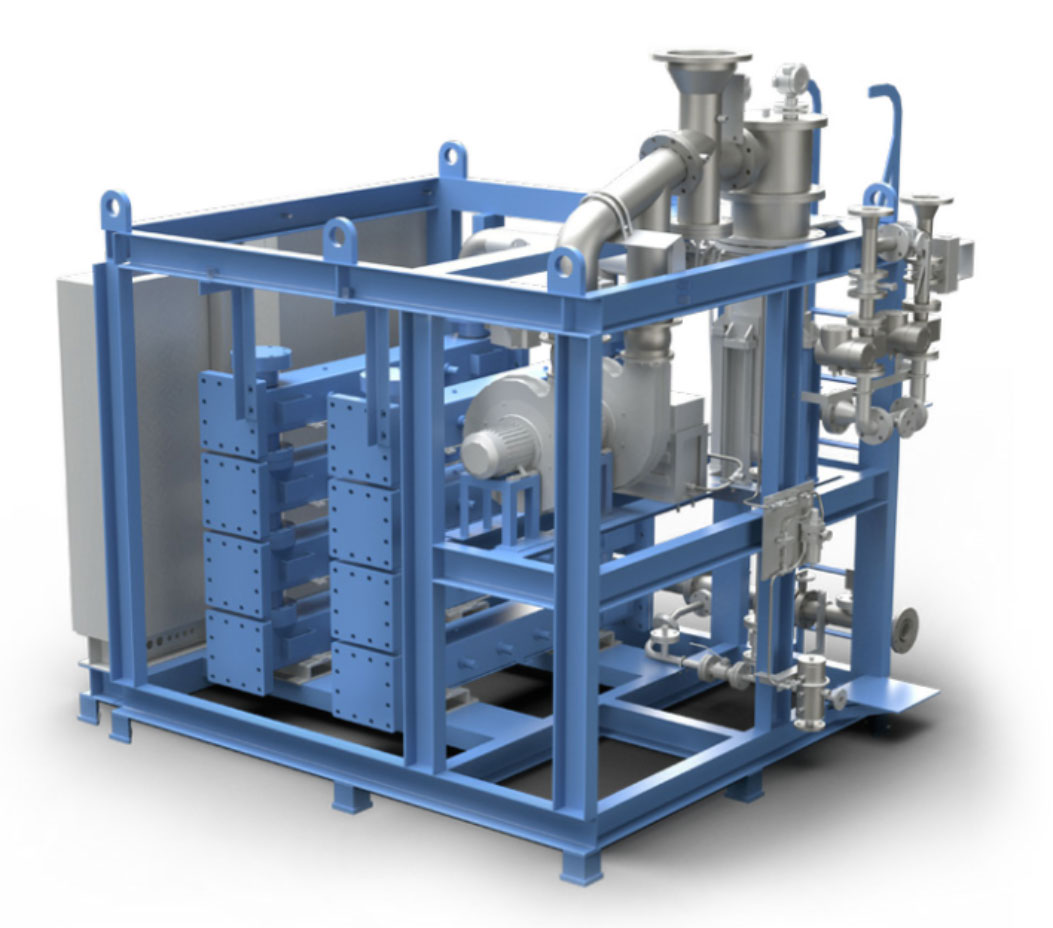

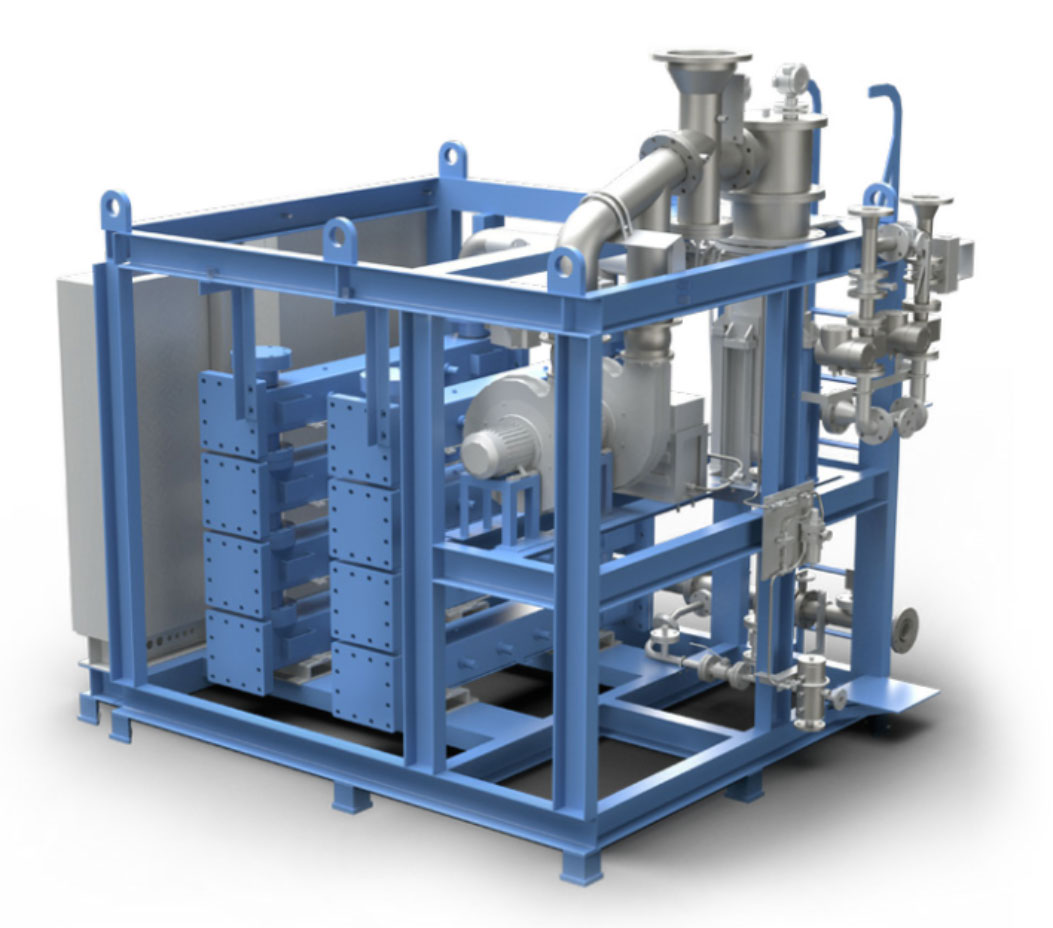

HiBallast NF is the world first and the ONLY Non-Filter(NF) type side stream electrolysis system developed by Hyundai Heavy Industries. The system will satisfy customer’s demands such as more cost effective, simpler and more reliable BWTS.

The treatment principle of the HiBallast NF is same as HiBallast except for filtration, which consists of electrolysis treatment during uptake and neutralization during discharge. This new development enables existing HiBallast modified to HiBallast NF and vice versa depends on customer’s option. The models with maximum treatment rated capacities are ranged between 75 m3/h and 10,000 m3/h.

The system is an adaptation of the original HiBallast system with the NF suffix denoting this model has no filter. This new model definitely brings much benefits to the customers such as saving CAPEX, OPEX, installation space and enhancing efficiency of engineering and operation eliminating problems associated with filter clogging and the need for back flushing.

The treatment principle of the HiBallast NF is same as HiBallast except for filtration, which consists of electrolysis treatment during uptake and neutralization during discharge. This new development enables existing HiBallast modified to HiBallast NF and vice versa depends on customer’s option. The models with maximum treatment rated capacities are ranged between 75 m3/h and 10,000 m3/h.

The system is an adaptation of the original HiBallast system with the NF suffix denoting this model has no filter. This new model definitely brings much benefits to the customers such as saving CAPEX, OPEX, installation space and enhancing efficiency of engineering and operation eliminating problems associated with filter clogging and the need for back flushing.

| Operational Principle | Operational Principle Electrolysis (Indirect type, side stream) |

|---|---|

| Average power consumption (per 1,000㎥/h) |

During Ballasting 50kW During Deballasting 1kW |

| Treatment point | Treatment point Electrolysis only during ballasting Neutralization during deballasting |

| Features | Low power consumption No pressure loss in main ballast line Minimum modification in main ballast line (in case of retrofit) No Ballast pump modification No by-pass line and related valves required |

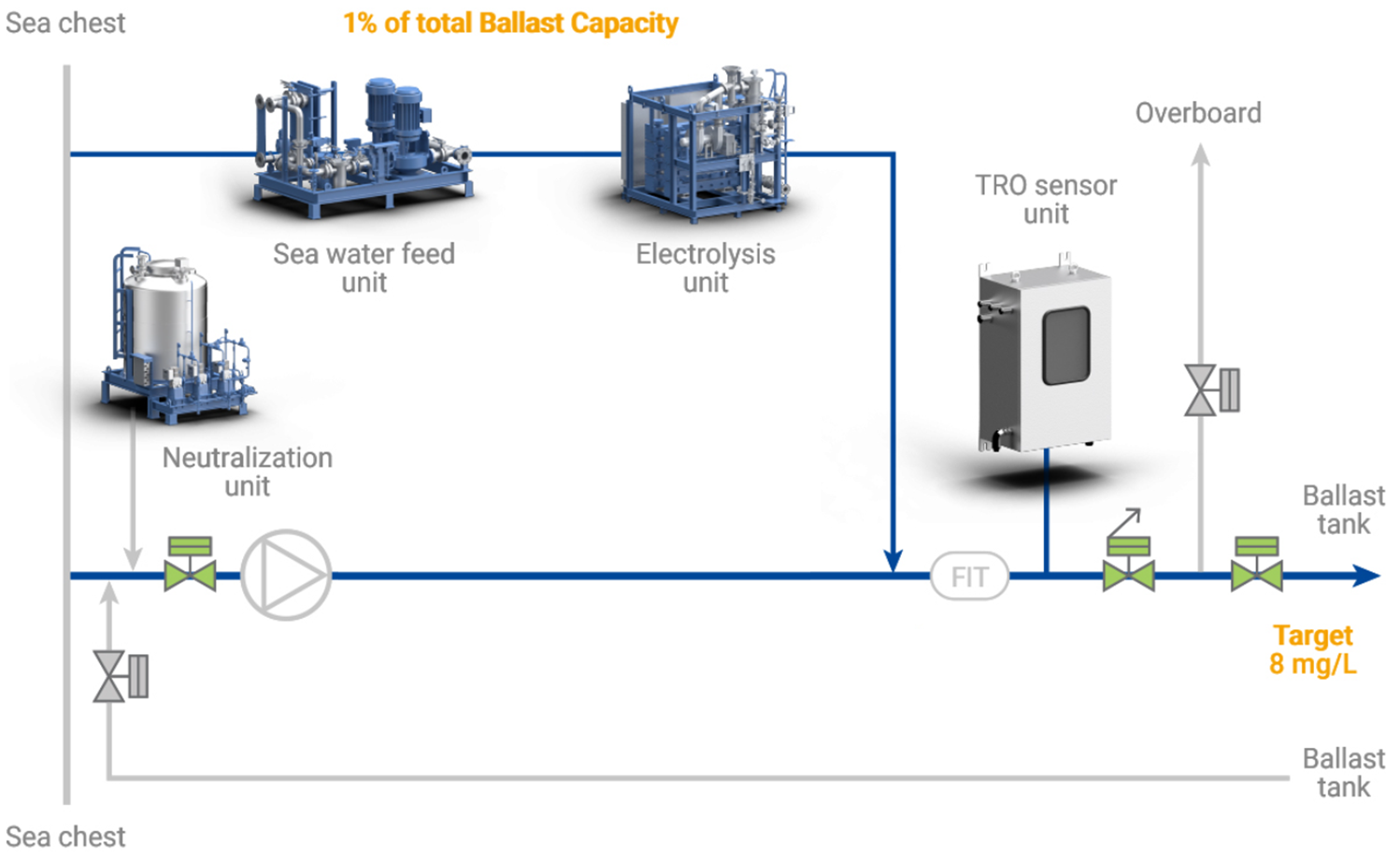

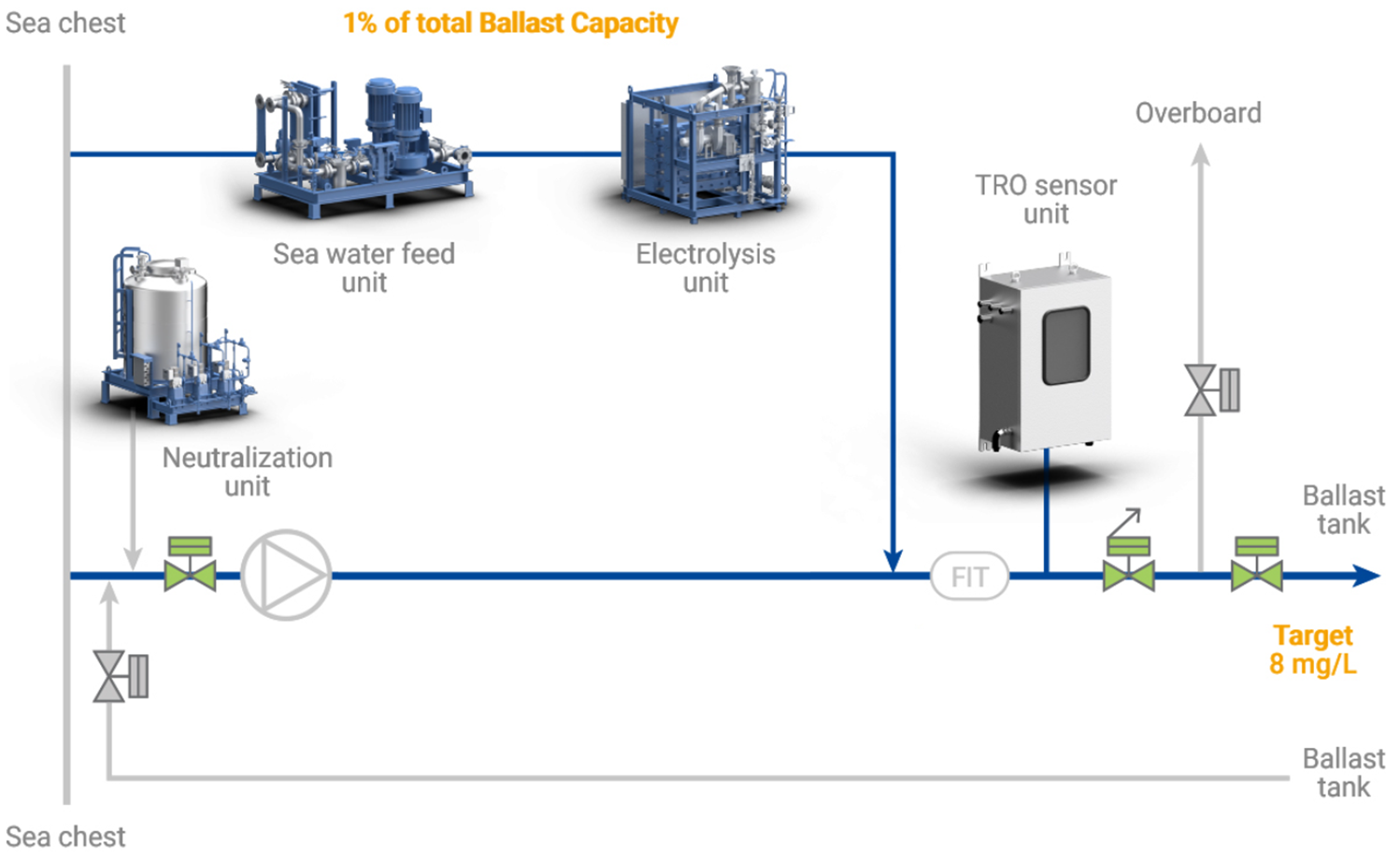

Flow diagram for ballasting (typical)

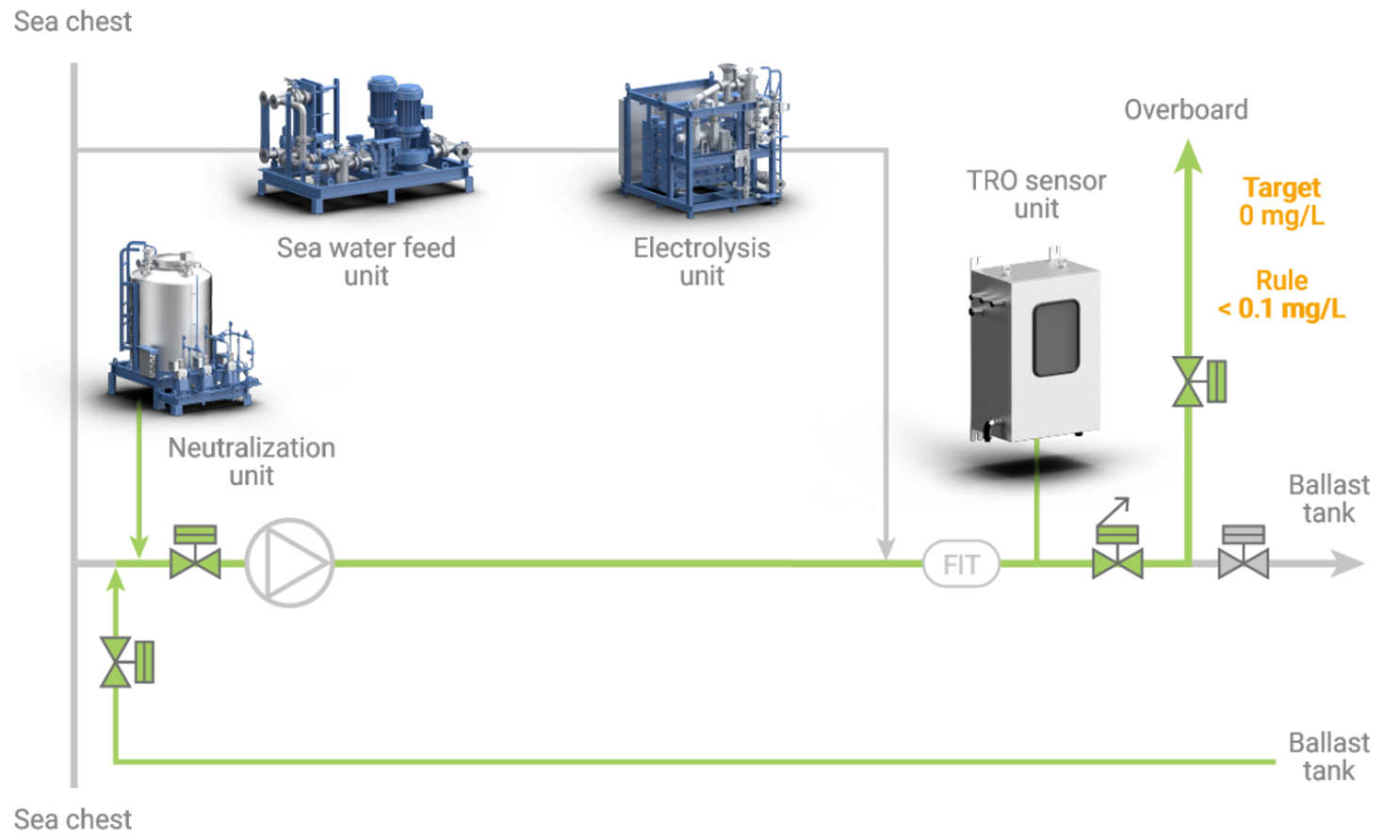

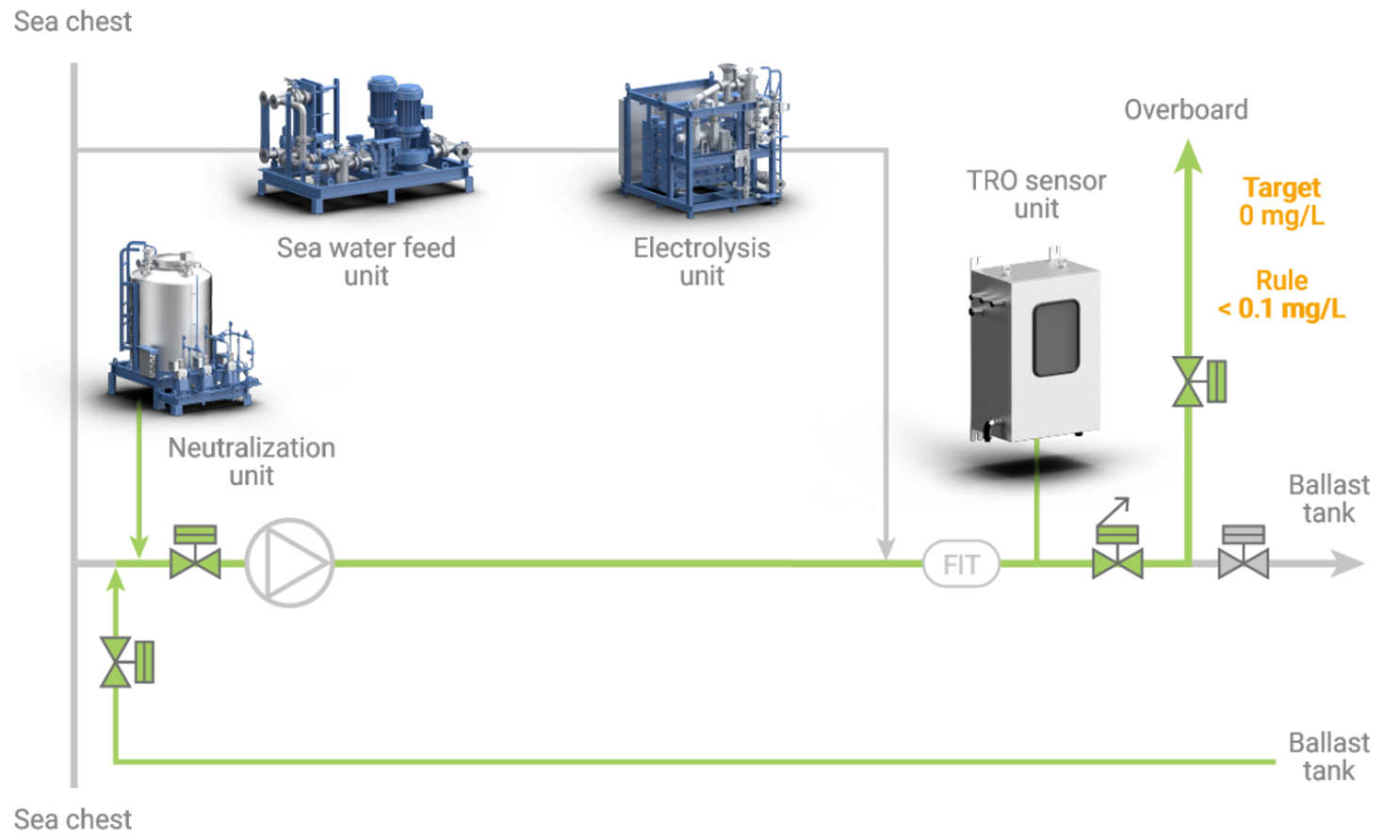

Flow diagram for de-ballasting (typical)