ALL PRODUCT

.jpg)

Flux Cored Wire

SC-460M

SC-71Ni2SR

SC-80M

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use Ar + 20-25% CO₂ mixed gas. -

Purpose

① Bridge construction

② Structural fabrication

③ Robotic welding

④ Transportation equipment -

Attribute

① High strength weathering grade steels(Corten steel)

② Good anti-porosity.

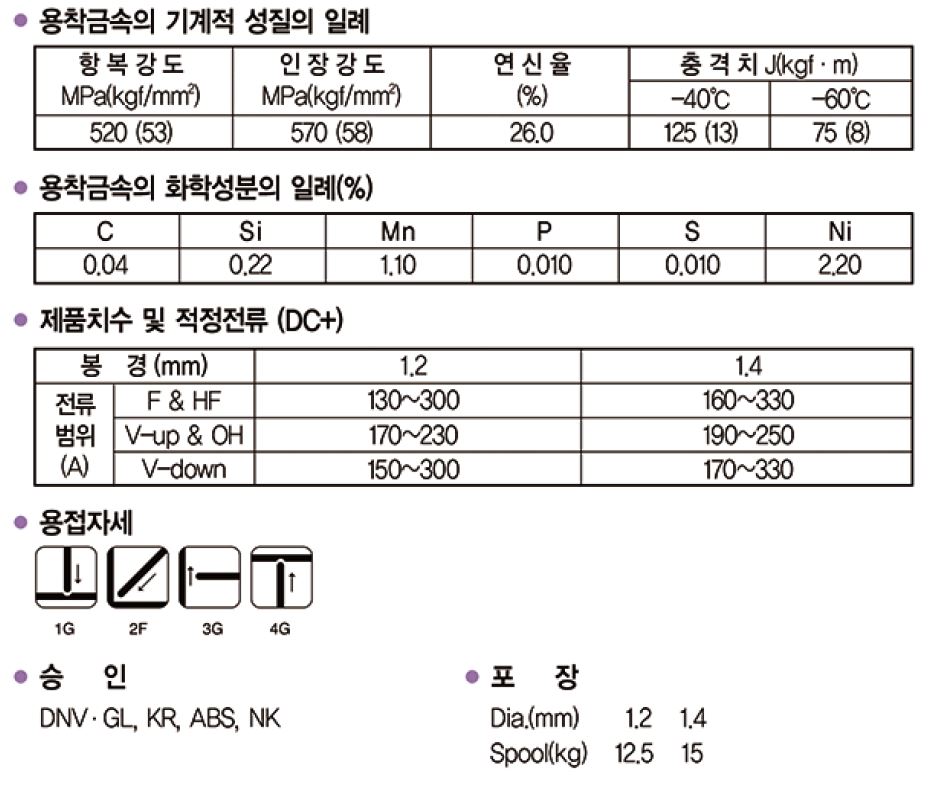

SC-71Ni2

-

Caution

① 강종, 판두께 및 구속도에 따라 다소 차이가 있으나 일반적으로 후판 및 구속이 큰 경우는 가접전에 저온균열을 방지하기 위해 적당한 예열 (50~150℃)이 필요합니다.

② 보호가스는 100% CO2가스를 사용합니다. - Purpose ① 조선, 해양구조물, 교량, 기계, 철골 등의 전자세 용접

-

Attribute

① 티타니아계 타입의 CO2 보호가스를 사용하는 전자세 용접용 와이어입니다.

② 아크안정성이 뛰어나며, 슬라그 박리성이 우수합니다.

③ 비드외관 및 형태가 양호하여 전자세 용접이 가능합니다.

④ -60℃의 저온에서도 충격치가 우수합니다.

SC-71MJ

- Caution .

-

Purpose

① Shipbuilding

② Pipe line

③ Offshore structure -

Attribute

① Good impact value at low temperature

② Smooth and stable arc with a fast freezing slag

③ Low hydrogen level(H5)

④ Designed for welding with Ar-CO2 mixture

⑤ Meets AWS D1.8 seismic lot waiver requirements

SF-71P

SC-81M

- Caution .

-

Purpose

① Construction machinery

② Bridge structures

③ Mining -

Attribute

① Smooth and stable arc with a fast freezing slag

② Good impact value at low temperature

③ Designed for welding with Ar+CO2 mixture

SC-81SR

- Caution .

-

Purpose

① Shipbuilding

② Offshore structure

③ Pipe line

④ Pressure vessel. - Attribute ① Good impact value at low temperature (As Welded and PHWT).

SC-81LT

- Caution .

-

Purpose

① Shipbuilding

② Offshore structure

③ Structural fabrication -

Attribute

① Good impact value at low temperature

② Smooth and stable arc with a fast freezing slag

③ Good CTOD value

SC-81Ni2M

.jpg)

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② Use Ar + 20-25% CO₂ mixed gas. -

Purpose

① Offshore structure

② Shipbuilding -

Attribute

① Good impact value at low temperature

② Good CTOD value

SC-80K2

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use 100% CO₂ gas. -

Purpose

① LPG and LNG storage tank

② Shipbuilding

③ Offshore structure -

Attribute

① High speed single or twin tandem welding

② Low hydrogen level (H4)

③ Low temperature service

Supercored 81-K2MAG

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use Ar + 20-25% CO₂ mixed gas. -

Purpose

① Offshore structure

② Shipbuilding -

Attribute

① Good impact value at low temperature

② Smooth arc and low spatter level

SC-460

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use 100% CO₂ gas. -

Purpose

① Shipbuilding

② Structural fabrication

③ Offshore structure -

Attribute

① Good impact value at low temperature service steel

② Low hydrogen level (H5)

③ High tensile steel (EH47 Grade)

Supercored 81-K2

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use 100% CO₂ gas. -

Purpose

① Offshore

② Shipbuilding

③ General fabrication -

Attribute

① Good impact value at low temperature

② Smooth and stable arc with a fast freezing slag

③ Low hydrogen level (H4)

④ Meets AWS D1.8 seismic lot waiver requirements

Supercored 81MAG

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use Ar + 20% CO₂ mixed gas. -

Purpose

① Offshore structure

② Shipbuilding

③ Mining

④ Petrochemical industry -

Attribute

① Good impact value at low temperature (as welded and PHWT)

② Low hydrogen level (H4)

SC-80MR

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use Ar + 20-25% CO₂ mixed gas. -

Purpose

① Offshore structure

② Heavy equipment

③ General fabrication -

Attribute

① Suitable for root-pass and multipass welding

② Good impact value at low temperature

③ Low spatter

④ Good anti-porosity

SC-70ML

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use Ar + 20-25% CO₂ mixed gas. -

Purpose

① General fabrication

② Heavy equipment

③ Offshore structure -

Attribute

① Good impact value at low temperature

② Semi-automatic and automatic applications

③ Good anti-porosity

④ Meets AWS D1.8 seismic lot waiver requirements

SC-71MSR

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use Ar + 20% CO₂ mixed gas. -

Purpose

① Pipe line

② Offshore structure

③ Pressure vessel - Attribute ① Good impact value at low temperature (As Welded and PHWT)

SC-71SR

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② High-voltage or high-speed for one-side welding might cause hot cracking on the root bead.

③ Use 100% CO₂ gas. -

Purpose

① Pipe line

② Offshore structure

③ Pressure vessel -

Attribute

① Good impact value at low temperature (As Welded and PHWT)

② Meets AWS D1.8 seismic lot waiver requirements

SC-81Ni2

-

Caution

① For preheating guidelines, please refer to your local standards and codes relative to your best practices.

② Use 100% CO₂ gas." -

Purpose

① Shipbuilding

② Offshore structure

③ Structural fabrication -

Attribute

① Good impact value at low temperature

② Good CTOD value

SC-EG3

- Caution ① Use 100% CO₂ gas.

-

Purpose

① Shipbuilding

② LPG and LNG storage tank -

Attribute

① Electro gas arc welding process

② High deposition(vertical up butt welding)

③ Low temperature service