ALL PRODUCT

Hyundai Welding Co., Ltd. is an authorized OEM company of HHI BWTS and covers sales, design, fabrication, commissioning, and training.

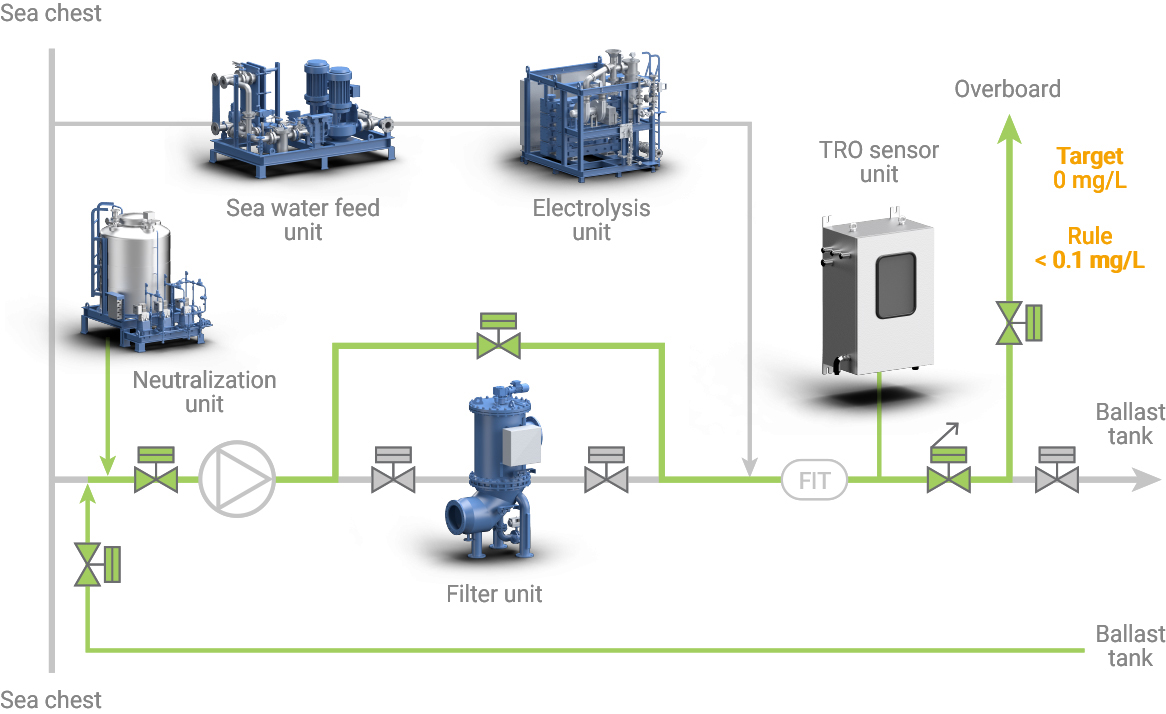

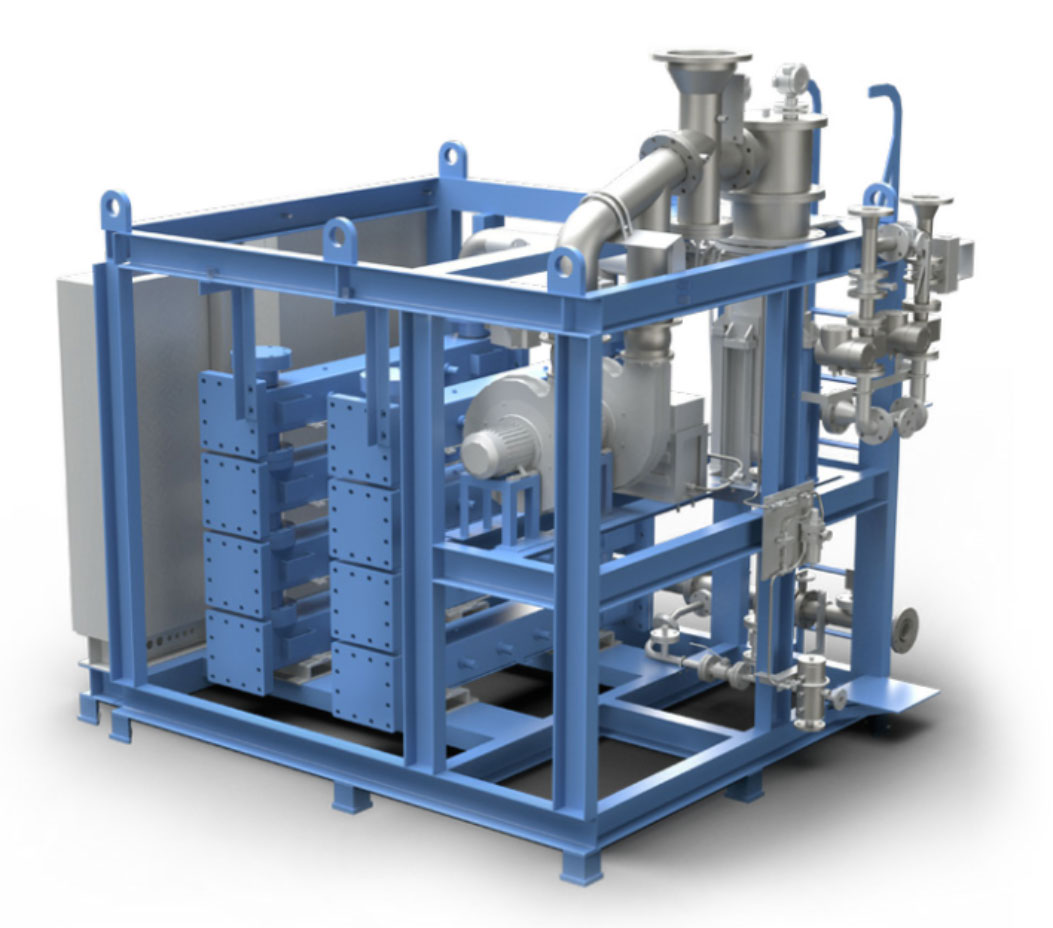

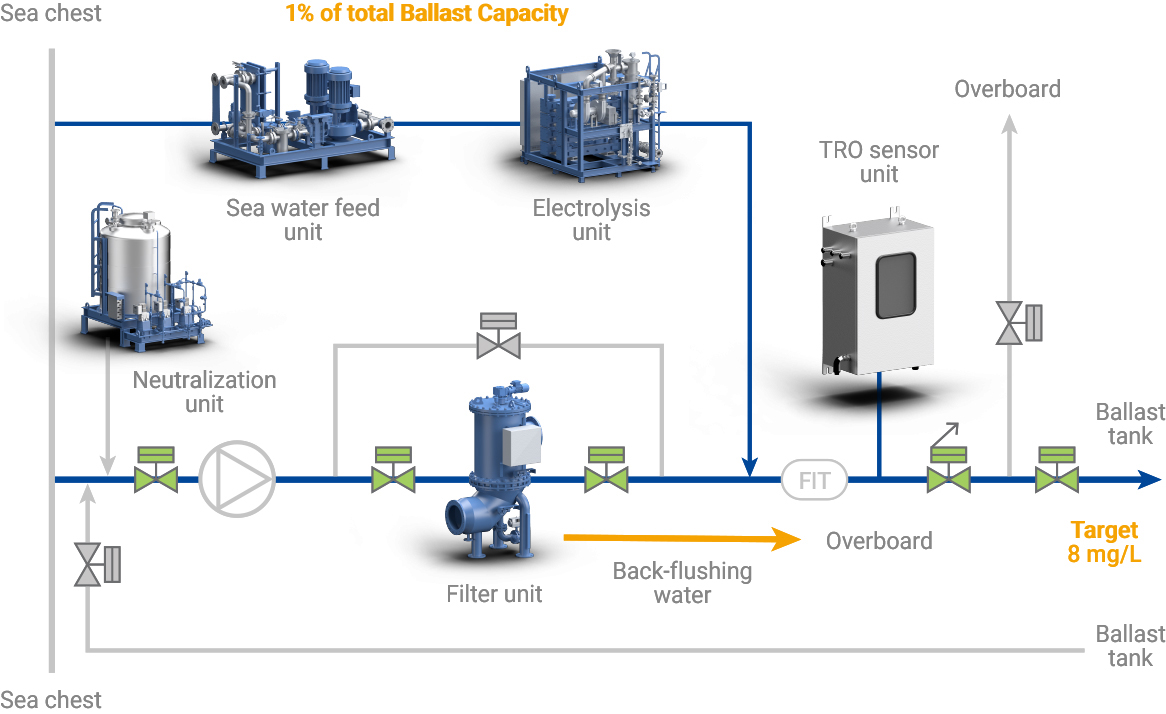

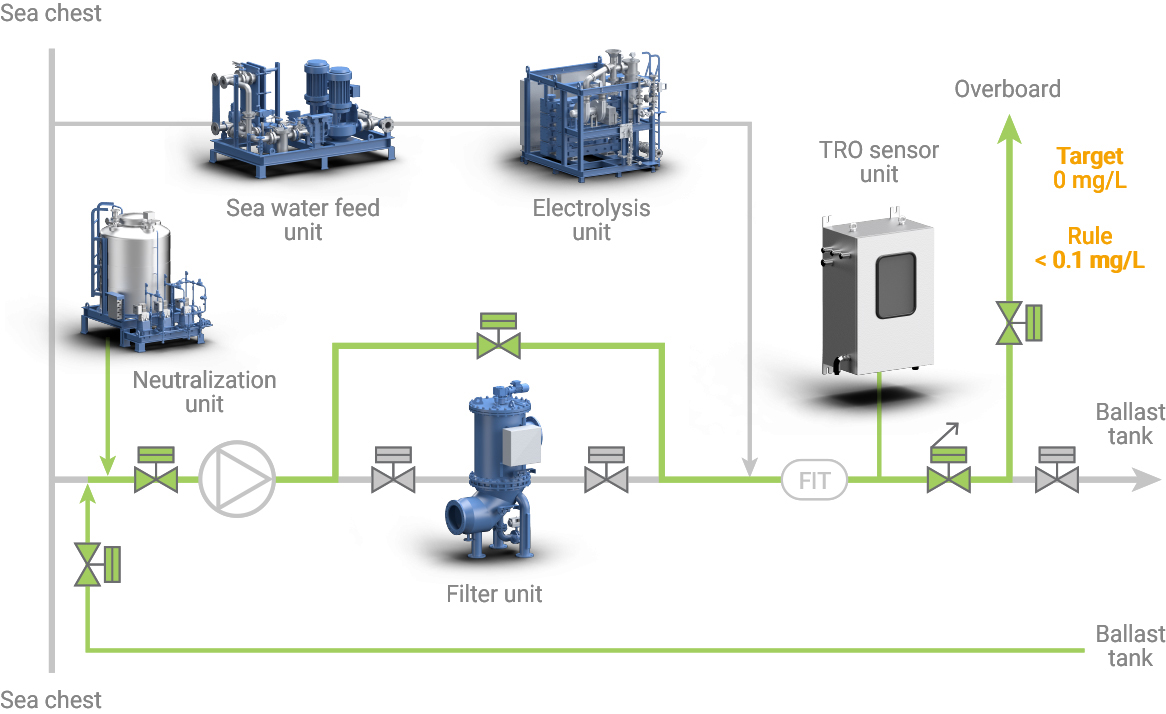

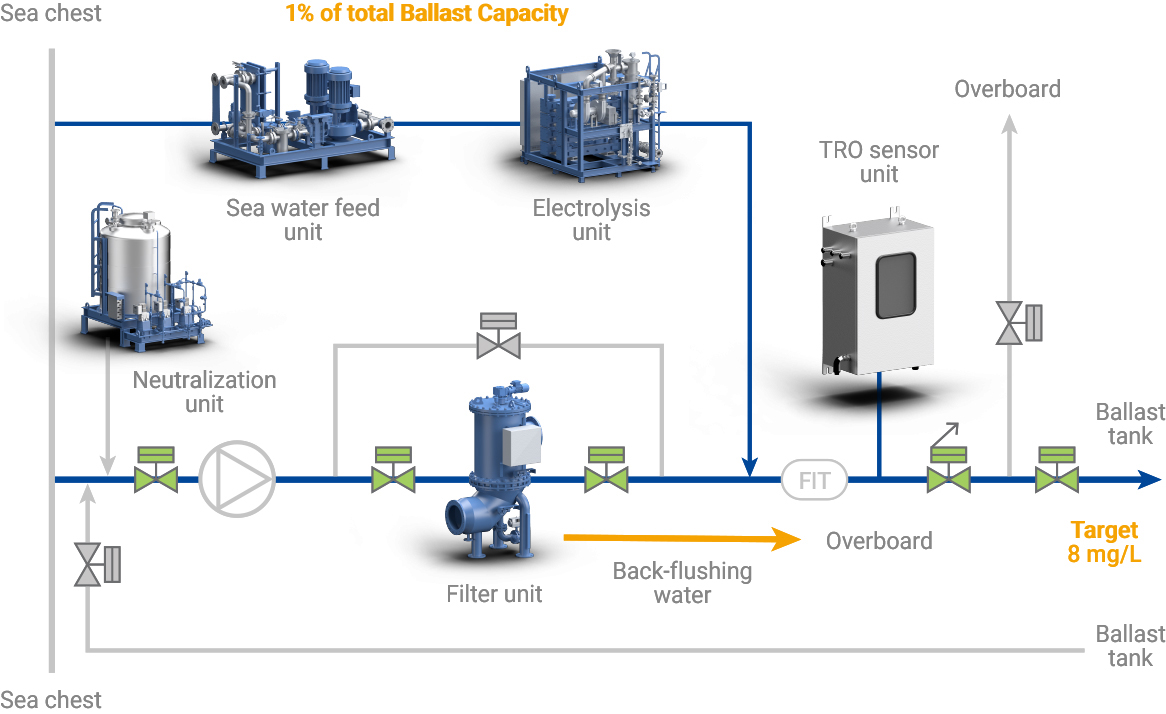

The HiBallast system is based on indirect (side-stream) electrolysis technologies and it is composed of major equipment such as, filters, electrolysis unit, neutralization unit, and a TRO sensor unit.

The filter has an automatic back-flushing function and physically removes harmful marine organisms, larger than 50μm, infrom the ballast water. In order to treat microorganisms smaller than 50μm that pass through the filter, a high concentration (but, less than 1,000 mg/L as Cl2) of hypochlorous acid is produced by indirect electrolysis and injected into the ballast water pipe of the ship.

If the ballast water is discharged without neutralization after the treatment, it may have a harmful effect on the marine environment. Therefore, the neutralization agent is injected to remove the remaining disinfectant in the ballast water before discharge.

The filter has an automatic back-flushing function and physically removes harmful marine organisms, larger than 50μm, infrom the ballast water. In order to treat microorganisms smaller than 50μm that pass through the filter, a high concentration (but, less than 1,000 mg/L as Cl2) of hypochlorous acid is produced by indirect electrolysis and injected into the ballast water pipe of the ship.

If the ballast water is discharged without neutralization after the treatment, it may have a harmful effect on the marine environment. Therefore, the neutralization agent is injected to remove the remaining disinfectant in the ballast water before discharge.

| Operational Principle | Filter + Electrolysis (Indirect (side stream) type) |

|---|---|

| Average power consumption (per 1,000㎥/h) |

During Ballasting 50kW During Deballasting 1kW |

| Treatment point | Water treatment only during ballasting Neutralization during deballasting |

| Features | Low power consumption In the low salinity area, the electrolysis unit of HiBallast is possible to operate with seawater that is only 1% of the total ballast water capacity to be treated. |

Flow diagram for ballasting (typical)

Flow diagram for de-ballasting (typical)